The word ‘Lean’ has been used throughout the west since Womack & Jones created the term in their now famous text “The machine that changed the world”.

The Lean programme offers five key steps:

- Specify value from the standpoint of the end customer.

- Identify all the steps in the value stream, eliminating, whenever possible, the steps that don’t create value.

- Make the value-creating steps occur in tight sequence so the product will flow smoothly toward the customer.

- As flow is introduced, let customers pull value from the next upstream activity.

- Seek perfection, as value is specified, value streams are identified, wasted steps are removed and flow and pull are introduced. Continue until a state of perfection is reached in which perfect value is created with no waste.

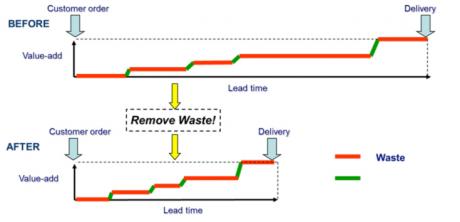

The attached diagram shows how removing waste from a process reduces the time from order to cash. As a result, process times are shortened allowing more work to be done by the same staff. The knock-on effect is a reduction in cost and quality improvement with the removal of non-value adding processes.

Companies implementing Lean also see an improvement in health and safety performance. Utilising 5s Worplace Management throughout the company ensures that health and safety issues are highlighted and removed. Some companies have added a 6th Step for safety to focus on the removal of potential issues.

Lean can be utilised in any business or industry sector and should be implemented across all parts of the value stream including sales and marketing, design, manufacturing, warehousing and shipping, for maximum gains.

The Skills4Work Lean Programme (Competitive Edge) is designed as an organisational change programme that delivers:

- Best practice productivity system consultancy with expert mentoring and support.

- Implementation processes that are aimed at creating internal capability and the capacity to lead and sustain change leading to improvements in quality and delivery.

- Modules that deliver best practice productivity system theory, processes, tools and work practices.

- Opportunity to link the implementation of the programme to achievement of qualifications.

- A programme for senior management that develops the internal capability to sustain on-going continuous improvements and a positive workplace culture.

- A programme for shop-floor employees delivered onsite in the workplace.

Both research and practitioner experience shows that Lean transforms business performance, as has been proved with its implementation in thousands of global companies including Johnson & Johnson, Black & Decker, Boeing, Baxter Healthcare, Bell Helicopters, Cessna Planes and Coca Cola.

Some of the New Zealand companies benefiting from the programme include Stainless Design, Pacific Aerospace, NuFarm, Proform Plastics, District Heath Boards, Image Holdings and some banks and councils.

Download Files:

Article for NZ Engineering News – A Brief on the Lean Programme